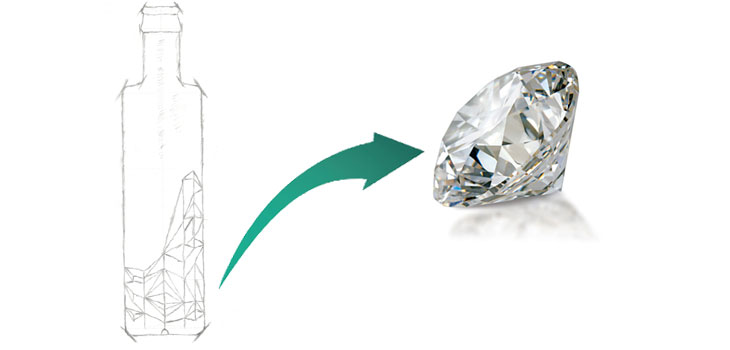

Step1:Submit design

We will understand the needs of customers, conduct sketch design, meet the requirements of customers under the premise of meeting production needs, and complete the first draft design.

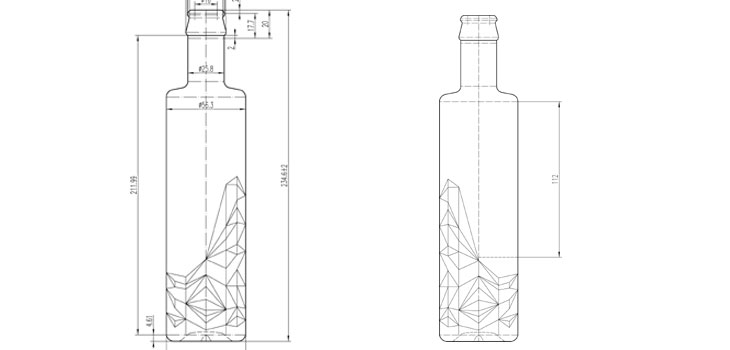

Step2:2D Drawing Design

After understanding the customer's needs, our designers will design the 2D drawings, and after completion, we will check the parameters for the customer and confirm the signature. Prepare for 3D design.

Step3:3D samples

After completing the drawings, we recommend that customers make 3D samples, which can save costs and time. By checking the 3D samples, the design can be adjusted in more details to make the glass bottle perfect.

Step4:Mold making

After confirming the 3D samples, the glass sample molds are generated. High-quality mold carving can make the glass samples more perfect.

Step5:Glass sample making

The production of glass samples is the most critical part before mass production. The final effect can be checked by making glass samples. After the glass samples meet customer requirements, mass production of glass bottles will begin.

Step6:Mass production

After confirming that the sample is perfect, our excellent and fast production team will finish mass production with high quality.